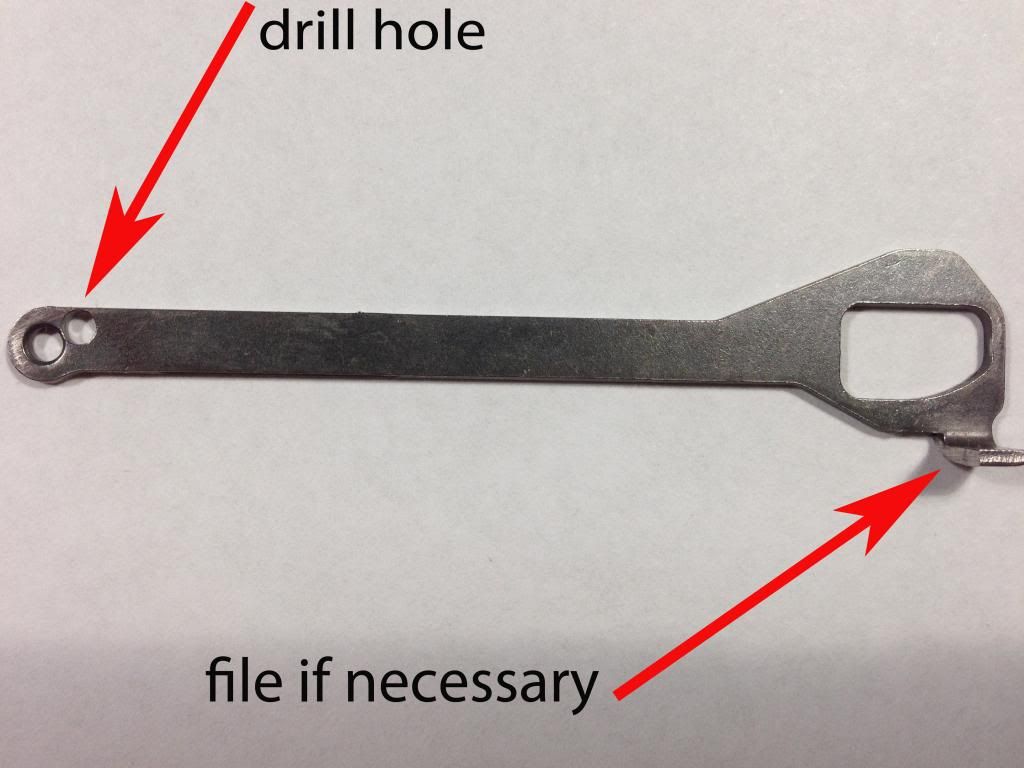

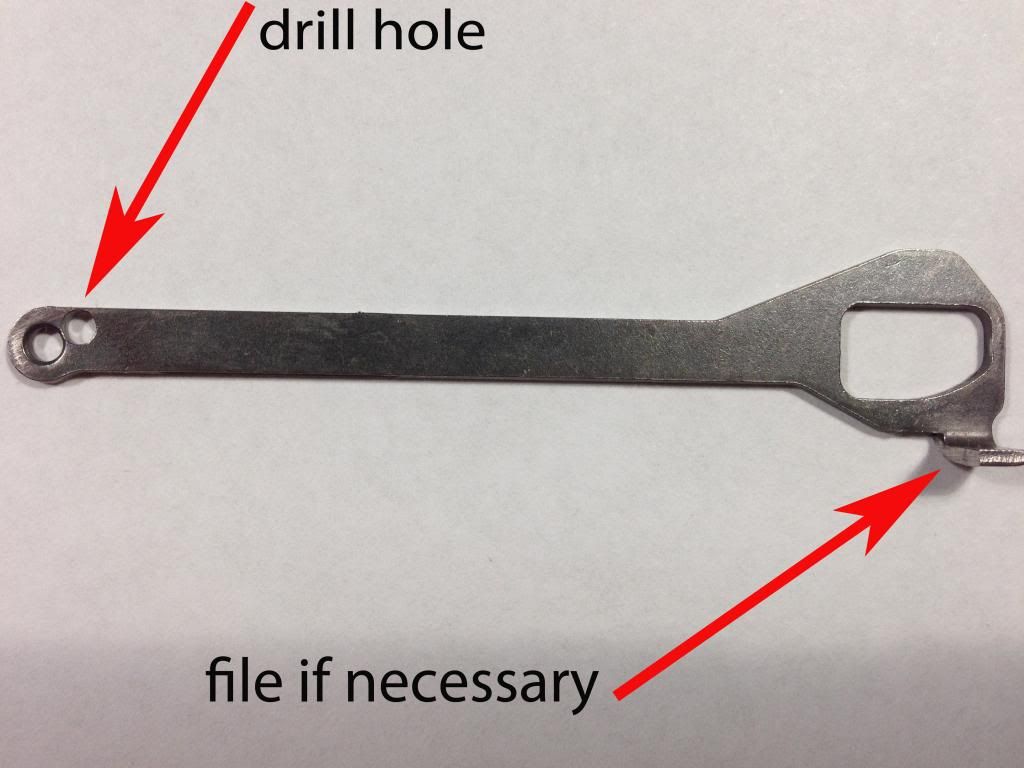

I have seen posts of complaints about the 1/4 inch of trigger take-up, before the hammer starts to move. This is easy to eliminate, if you can drill a 3/32 diameter hole. Remove the trigger bar, drill that 3/32 inch hole to the rear of the original front hole in the trigger bar, just slightly higher and close to the original hole, without breaking into the original hole. Note that it doesn't have to be quite as high, or as close to the original hole, as shown in the photo. As long as you do not break into the original hole, you can always revert the LC9 back to the original pull, just by installing the original trigger bar hole back into the trigger pivot pin(#2), as it originally came from the factory.

By drilling the new hole, you remove most all of the take-up, plus you move the trigger break point forward 1/4 inch. The results are almost the same as the Galloway Precisions new 35% trigger bar. When you assemble the gun, if after racking, and pulling the trigger does not move the hammer, you just need to file a small amount of metal off the leading edge of the trigger bar tab, to get the hammer reset. Assemble and test. If still no reset, do this again, until the hammer pulls. It is best to only file a maximum of .005 inch off at a time and test. When finished you have removed nearly all the take-up, you have moved the deep breaking trigger point forward 1/4 inch, and nothing else has changed with the gun. All safeties still function, the hammer pulls back to the factory point, you just shortened the pull and moved it forward by 1/4 inch.

Bob

By drilling the new hole, you remove most all of the take-up, plus you move the trigger break point forward 1/4 inch. The results are almost the same as the Galloway Precisions new 35% trigger bar. When you assemble the gun, if after racking, and pulling the trigger does not move the hammer, you just need to file a small amount of metal off the leading edge of the trigger bar tab, to get the hammer reset. Assemble and test. If still no reset, do this again, until the hammer pulls. It is best to only file a maximum of .005 inch off at a time and test. When finished you have removed nearly all the take-up, you have moved the deep breaking trigger point forward 1/4 inch, and nothing else has changed with the gun. All safeties still function, the hammer pulls back to the factory point, you just shortened the pull and moved it forward by 1/4 inch.

Bob